CRANE COMPONENTS

Crane components:

Crane cabs

The crane cab is mounted on the crane and designed and suitable for control of crane mechanisms and for protection of crane operator and the installed equipment from climate and thermal effects.

We produce open and closed crane cabs. Closed cabs are equipped with air conditioning, heating stove. The crane cabs complete set is discussed with the customer: joysticks or command controller, electrical equipment, type of protection pane, etc.

Chair of the operator (driver).

Anti-vibration chairs are designed and suitable for installation in gantry cranes. They meet the requirements of NPAOP 0.00-1.01.07 (register of the normative acts for worker safety and health).

Snatch blocks (diameter up to 1000mm).

Snatch blocks deflect a rope in load-lifting mechanisms in the required direction and level force.

Buffers BP50, BP80, BP100, BP160, BP200, BP250.

They are designed and suitable for mitigation of possible impact of the lifting crane against stops.

Brakes TKГ- 500, TКГ - 600.

Cranes brakes with electro-hydraulic drive are designed and suitable to hold and stop the gears shaft.

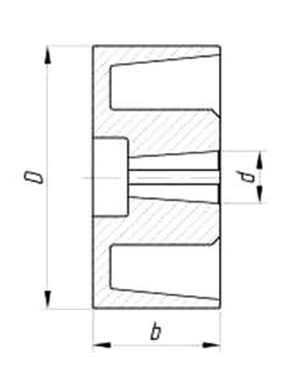

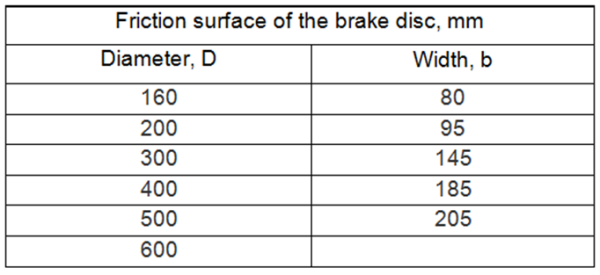

Brake discs (diameter up to 500 mm).

Brake disc is a part used in materials-handling machines. The main function of the bake disc is an effective stop and holding of gears shaft in stationary condition while electric motor is turned off.

Brake disc is a wide-rim wheel. Usually double-block spring brakes are used in cranes gears, with a short-stroke AC electromagnet. In addition, it can be used the brakes, which work on the electro-hydraulic pusher mechanism.

Usually a brake disc is mounted between the electric motor shaft and the input shaft of the gear, or on the backside of the gears input shaft. When mounted on the gears working outdoors, the brake disc should be covered with protective case against atmospheric condensation.

The working surface of the brake disc shall have: accuracy of manufacturing not less than class 4 in accordance with GOST (all-Union State Standard) 25346, GOST (all-Union State Standard) 25347; run-out, ovality and conicity not more than 0,0005D; hardness not less than 35 ... 45 HRC (steel bake discs) or 250 ... 300 HB (iron bake discs).

Recommended materials for brake discs is steel 45, steel 35 СГ or steel 65Г. For brake disc of traveling and rotation mechanisms with operation modes 1M - 5M the cast iron with stress-related properties not less than СЧ 28 according to GOST (all-Union State Standard) 1412 is allowed to use.

The groups of operating mode for mechanisms 1M-6M and the classes of mechanism’s use A0-A6 should be identified in accordance with GOST (all-Union State Standard) 25835.

Brake disc must be replaced in the following cases:

- If there are any cracks and breaks on working and mounting surfaces

- If the wear of the rim working surface is more than 25% of the primary thickness

- If the size of the different asperity’s on the surface of the brake disc is more than 0,3 mm, its total area is more than 10% of the area of the working surface.

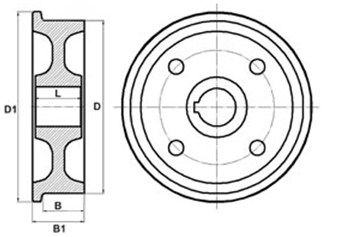

Typical dimensions of the brake disc.

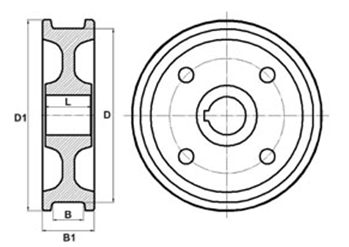

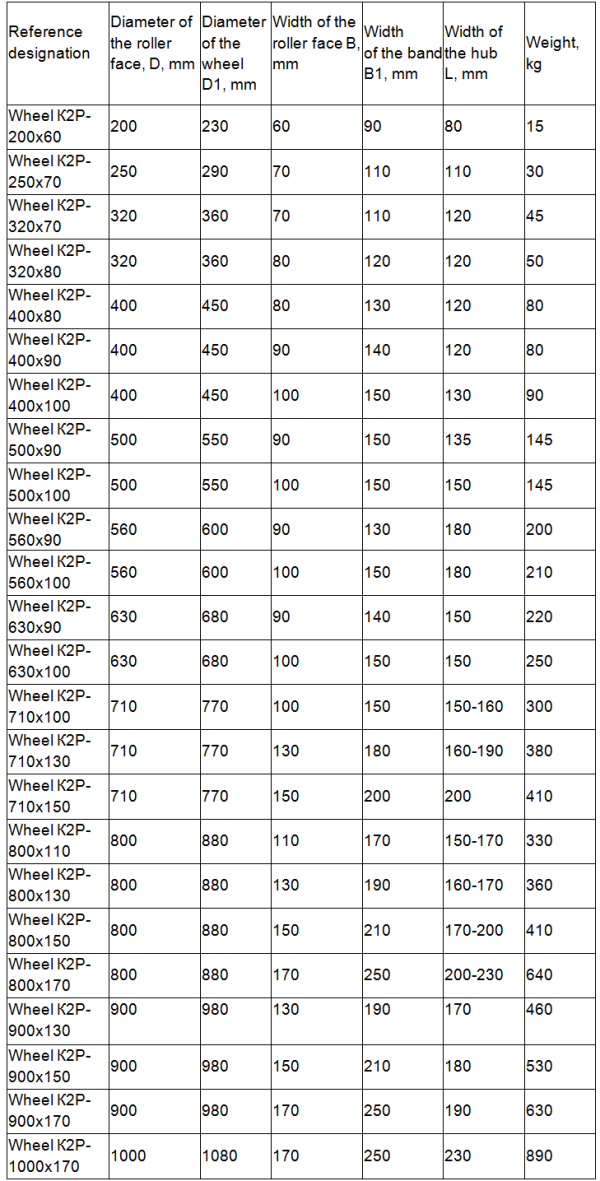

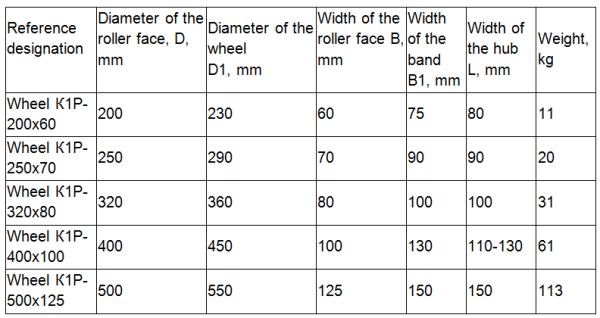

Crane wheels with diameter up to 1000mm.

To move a crane on rails, the crane drive wheels are used. They are subjected to a huge load, therefore in case of wear the crane wheels shall be timely replaced in order to keep cranes in operation.

Crane mechanisms are a necessary part of all the production process, so the approach to choosing of the right lifting equipment must be serious, otherwise there is a risk to buy low-quality equipment which will demand expensive repair almost every 3-4 months.

Our company offers various crane wheels with diameters from 200 mm up to 1000 mm in accordance with GOST (all-Union State Standard) 28648-90.

You can buy with us a crane wheel according to your drawings!

The double-flange, single flange, and flangeless crane wheels with cylindrical band as well as single flange crane wheels with conical band are used in cranes. The double-flange crane wheels are prevailing. Furthermore, crane wheels have different hubs. The inner diameter of the hub is designed for the installation either of ball bearings, or directly of the shaft with two journal-boxes on roller bearings.

The blanks of crane wheels are made by pressing or smith forging of steel 65Г (45) or founding of steel 65ГЛ (45ГЛ) with subsequent machining of crane wheels working surfaces. Working surfaces of crane wheels are heated (sorbitized) to a hardness of 320 - 390 HB with a smooth junction from hardened to non-hardened layers. The depth of the hardened zone is up to 40 mm depending on the diameter of the crane wheel.

A crane wheel as а set with the shaft and bearings (journal-boxes) is called a wheel unit. The connection of the driving wheel to the drive usually is carried out by means either of a pinion or flange mounted on the shaft of the crane wheel or girt gear mounted on the band of the crane wheel. The crane wheels connected to the mechanism of crane movement or traveling trolley are called leading (driving wheel) wheels; the other wheels are driven (loose wheel). Usually the half of the crane wheels are the leading ones.

We can supply both separate crane wheels and wheel units.

Preliminary drawing of double-flange crane wheel

Table of the main types and sizes of two-flange crane wheels according GOST (all Union State Standard) 28648-90:

Preliminary drawing of single flange crane wheel

Preliminary drawing of single flange crane wheel

Table of the main types and sizes of single flanged crane wheels according GOST (all-Union State Standard) 28648-90:

We offer (spare-parts for cranes) double-flange, single flange, and flangeless crane wheels manufactured in standard sizes and according to client’s drawings.

Crane Hooks

- forged

- laminated

Crane grips etc.

Crown wheels with diameter up to 500 mm, to 10 module.

Flanges.

Shafts.

Bushings.

Box-type workpieces.