CRANE’S SAFETY DEVICES OHK (CRANE LOAD LIMITER)

PST manufacturing group is a manufacturer of lifting equipment and offers for sale a wide range of components to it. Also our company has maintenance and assembling teams specializing in the maintenance and commissioning of all types of cranes (including work in active electrical systems up to 1000V). Skilled experts of maintenance and assembling teams equip all types of cranes with radio control systems and frequency drive systems, with crane’s load limiters.

The trained specialists of our company carry out assembling, adjustment and subsequent servicing of the cranes load limiters with a built-in data logger of OHK type (CRANE LOAD LIMITER). PST manufacturing group is an official service center in the territory of Ukraine for maintenance and repair of safety devices used for load lifting cranes.

Crane load limiter with built-in data logger OHK-160M is intended for bridge and gantry cranes and used to protect the crane from overload while loads lifting, from intolerable wind overloads for cranes working outdoors, from loading distortions in containers at container cranes, as well for displaying of information about actual weight of load, load capacity level, and wind speed.

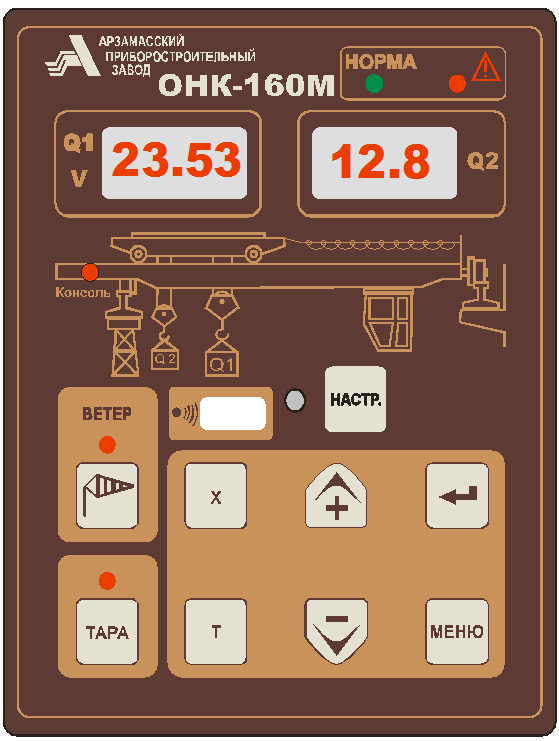

Front panel of the control unit (CU) of device OHK-160M.

The main features of the device OHK-160M

There are about twenty versions of the device OHK-160M, which differ by number, nominal value and design of used force sensors. The output signal from the force sensors is digital. The length of the cable that connects the sensor to the instrument can reach 150 meters (as standard the cable with length of 50 meters is delivered). The device keeps working in strong magnetic fields (up to 15000 A/m), which occur in metallurgy.

The device enables connection with a single cable up to 16 sensors to its input circuits that allows not only to measure the weight of large-sized goods, which are lifted by means of such gripping devices as cross beams, spreader plows, but also to estimate distortions by containers loading for container cranes and to stop lifting mechanism at intolerable distortion.

The device prevents from premature opening of the containers gripping device, as well as enables protection against ropes falling, allows estimating the total load on the bridge for grab cranes with separate lift and grip mechanisms and to switch off the lifting by exceeding of the overload capacity. The device enables to display on indicators the net weight of lifted load (without tare weight).

The device has a connector for wind speed sensor, when the sensor is connected, the indicator displays the speed of the wind, and activates a warning alarm by exceeding the maximum permissible wind load.

Structurally the device looks like a compact control unit (CU), size 240 x 174 x 85 mm, weight 2,35 kg, installed in the cabin. Supply voltage of the device 380 V, 50 Hz, power consumption - no more than 40 VA.

All versions have a built-in data logger of the cranes work and a real time clock. Data logger enables to receive information not only about the size of a lifted load and cranes exploitation rate, but also operation time of each electric drive. When you install an additional expansion box (EB, ordered separately) it is possible to record the operation time for each of the 8 cranes drives for accounting of running time in order to perform timely routine and preventive maintenance.

Tower crane load limiter OHK-160B LGFI.408844.025 Is intended for installation on tower cranes and serves to protect the crane from overload and overturn when lifting the load, to protect the working equipment from damage when working in restricted area (coordinate protection), as well as to display the information about actual loads, the limit load capacity, the crane load level, the offset value, and wind speed.

Built-in data logger (DL) enables recording and long-term storage of information about operating parameters of the crane, as well as about the cranes workload during the lifetime of the limiter.

Limiter enables:

- - stop of cranes mechanism when the crane hook load is more than 105% of the rated load capacity;

- - stop of cranes mechanism when reaching at least one of the determined restrictions of coordinate protection;

- - stop mechanism for loads lifting or lowering by accelerated winch if the weight of the load exceeds the limit when using accelerated winch;

- - sending the signal about approach to a limit of overload or coordinate protection into the crane control system;

- - sending the signal about exceeding the wind speed into the crane control system.

Limiter OHK-160C is intended for installation on self-propelled fluid-actuated jib cranes and serves to protect the crane from overload, to limit working areas of cranes equipment, which are defined by its design and environment (when working in restricted area or close to overhead power lines), to record crane operating parameters, and to display information of load, roll, and other parameters of the crane.

Built-in data logger (hereinafter - DL) enables recording, preprocessing, and storage of service information (including information about the company which programmed the device), the operational and long-term information about the crane operating parameters (including its operation rate) during the lifetime of the OHK (CRANE LOAD LIMITER).

Limiter enables:

- nonstop run; readiness time of the limiter is no more than 5 minutes after the power is turned on;

- reception and processing of up to twenty-four (depending on the version of the OHK (CRANE LOAD LIMITER)) DC discrete input signals with voltage of 10 to 30 V from the electrical circuit of cranes lifting mechanism (CLM), including signals of sensors of arms control position, for producing of corresponding control signals of output electronic keys according to the algorithm of limiter’s working program, as well as for recording of signs characterizing the state of crane equipment, to the data logger memory;

- sending of two relay DC control signals (12/24 V, 1,5 A), which disconnect or allow movement of crane equipment with reduced or any other speed, into the control system of the crane;

- Indication of the configuration of crane equipment, of the operation modes for crane and the OHK (CRANE LOAD LIMITER), as well as the crane operating parameters;

- LCD display backlight in the dark;

- Record (registration), storage and reading of telemetering data of the crane operating parameters from the built-in in OHK (CRANE LOAD LIMITER) data logger (RP);

- warning and alarm light and sound alarm;

- Programming of the OHK (CRANE LOAD LIMITER) for the specific type of crane (of certified specialists from specialized organizations);

- limiters self-diagnosis: testing of functional units of the OHK (CRANE LOAD LIMITER) blocks and sensors and control of condition of communication lines connecting BOI (information display unit) with units and sensors, control of connection of output electronic relays to executor and control of their blocking with jumpers.

- - environment temperature from - 45 up to + 55 °C;

- - relative air humidity up to 100% at temperature of 25 °C.

Level of protection of OHK (CRANE LOAD LIMITER) components cases (blocks and sensors) have version U according to GOST 14254-96: IR55 - for BOI; IR56 - for the other components. To learn more about our company you can visit the website of our company: www.pst.zp.ua

We offer mutually advantageous cooperation in equipment (reconstruction) of in your company available load lifting equipment with cranes load limiters with built-in data logger of OHK-160 series, which will ensure reliable and long-term work of equipment.