Cross beams, grippers, grabs

- Cross beams

Load cross beam is a load-carrying interim construction, located between the crane and the loads. Load cross beam is an integral part of lifting equipment for qualitative lifting and movement of big and nonstandard loads. Cross beams can be hanged up both on crane hook and on gripping parts of any other load gripping machines and mechanisms. Cross beam can be used for lifting of long-measuring and nonstandard loads and for lifting of loads in case if there are any height limitations.

Cross beams are characterized identified by gripping point.

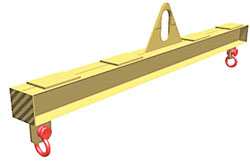

Lifting cross beams with gripping in the middle are used for lifting of different loads by means of end-capping devices or hoisting devices. They are heavy (about 3342 kg) and ensure minimum requirements to lifting height. For a complete elimination of load disbalance it is necessary to carry out its alignment on the center.

Those cross beams can lift loads up to 50 t. Overall dimensions of cross beams can be changed depending on client’s needs.

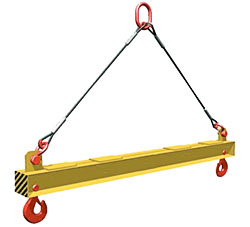

Lifting cross beams with a strapping on two points. This model enables lifting of smaller loads as compared with previous cross beams type but on considerably greater lifting height. This type of the cross beam can lift loads with out-of-level center of balance without leveling it while rising. This is the most common model. The item enables to rotate the load and thereby ensures convenient storing. The cross beams can be produced in different dimension types depending on client’s needs and manufacturer’s facilities.

Spreader cross beam with gripping in the middle. They are used for lifting of heavy massive loads. Due to presence of gripping in the middle, it is necessary to center the load before lifting. Cross beam’s dimension types should correspond to client’s needs.

Spreader cross beams with gripping along the edges. They are used for lifting of massive loads or those ones, which exclude possibility of pressure upon the parts of load or slings, which fasten loads to the cross beam. Such cross beams require to use four-leg rope for fastening to the cross beam hooks. This model fully excludes overbalance in any directions, the load centering does not required. Dimension types can be changed depending on client’s needs and manufacturer’s facilities. Successful lifting is achieved due to competent arrangement of loads slinging and reliability of the used cross beams.

Cross beam for direct stowage of the loads with length up to 12 m and weight up to 3000 kg inside 20’ and 40’ sea carrier. Our company has designed and produced a special cross beam, which enables line loading in a sea carrier, the loading can be made both in container on the ground and in container on the vehicle. Cross beam enables loading into the very depth of the container and storing in tiers.

- Grabs

Grab is a mounted crane gripping equipment designed for gripping, transfer, and carrying of loose goods, scrap metal, wood products etc. at a short distance. Grab for loose goods (hook grapple) uses the principle of penetration and load gripping. For better gripping the grab jaw can be equipped with teeth. The configuration of grab for loading /unloading of long load (pulpwood, logs, pipes etc.) is similar to bucket grab, but has jaws in the form of two claw-like catches (span-dogs).

The usage of grabs enables full mechanization of the loading operations.

Classification of grabs is made according to the following parameters.

1. According to loading material:

- two-jaw grabs or bucket grab (for bulk cargo);

- multijaw bucket (for large-sized loads);

2. According to path of jaws when scooping the load:

- with digging path;

- with feeding path.

The jaws of digging grabs go deep into the material («they dig it») at work.

The jaws of feeding grabs at work move along the straight horizontal line, at that the load, being dispersed in a thin layer, is fed and spooned.

3. According to type of jaws closing device and to kinematic features the grabs are divided in:

- rope grabs

- power grabs

All the rope grabs don’t have rigid kinematic coupling between the upper and lower cross beam of grab and their hanger unit on crane. These grabs come into operation by means of ropes of load lifting gear.

According to number of ropes the rope grabs are divided into:

- single-line grab

- two-line grab

- three-line grab

- four-line grab

- grabs with more than four ropes.

Power grabs are divided into two types:

1) Motor and electrohydraulic.The power cable connects the grab with the crane, this cable supplies power to electric motor of the jaws drive unit (gear-motor drive or hydraulic aggregate).

2) Pneumatic and hydraulic.

The grab itself is equipped only with actuating devices: hydraulic or pneumatic cylinders. These grabs are connected to the crane with hydraulic or pneumatic lines.

- Gripping devices

Gripping devices are special devices for loads lifting and transfer.

They are intended for transportation of metal (in coils) and other materials and constructions in horizontal (vertical) position.

During loading and unloading operations, the special hoisting devices are used for loads fastening and transport - gripping devices. Depending on a configuration, durability and load type, different types of gripping devices are used for transportation and loading. Our company produces the following gripping devices:

- Gripping device for horizontal movement of a sheet;

- Gripping device for vertical lifting and moving of a sheet;

- Gripping device for horizontal movement of a sheet at a strapping with a big corner between branches;

- Gripping device for pile of sheets;

- Gripping device for reinforced concrete rings;

- Mount clamp;

- Gripping clamp for load lifting in vertical position;

- Jaws gripping device for round items lifting in horizontal position;

- Jaws gripping device for rolled section (rail clamp);

- Jaws gripping device for curb stone;

- Jaws gripping device for barrel lifting in horizontal position;

- Jaws gripping device for barrel lifting in vertical position;

- Telescope gripping device for pellets (crane-fork);

- Gripping device for roll of steel;

- Gripping device for stairways lifting;

- Gripping devices for tubes lifting (in pairs);

- Magnetic load lifting gripping devices.

- Pluggable load gripping device for direct stowage of the loads with length up to 12 m and weight up to 3000 kg inside 20’ and 40’ sea carrier. Gripping device is intended for fork-lift truck (it is fastened on fork-lift truck’s work tool) with weight-carrying capacity of 16-20 t, depending on weight of lifted loads.